FireGuard System – Repairs Damaged & Defective Flue Liners

The Problem

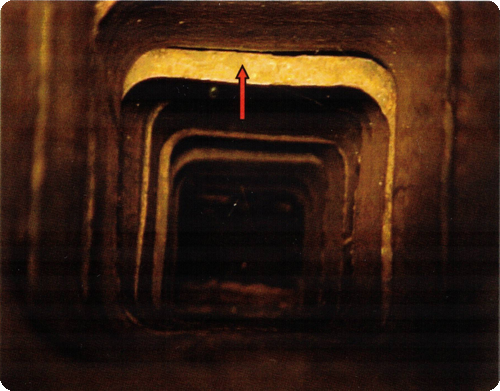

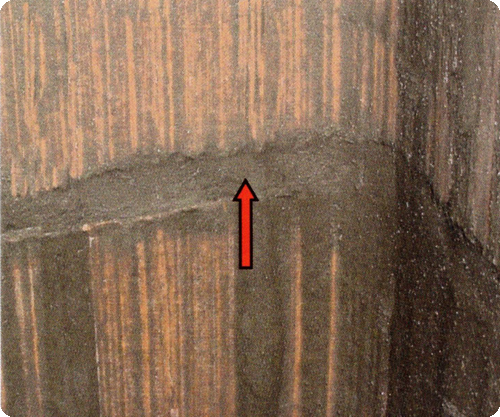

1. Misaligned flue liners.

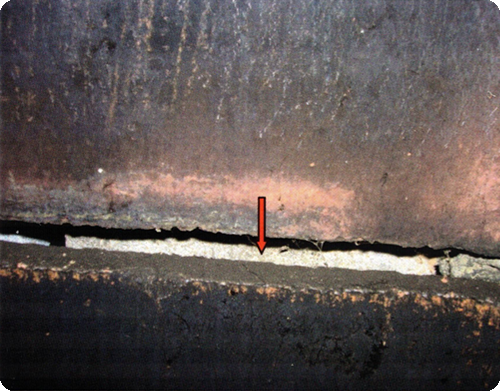

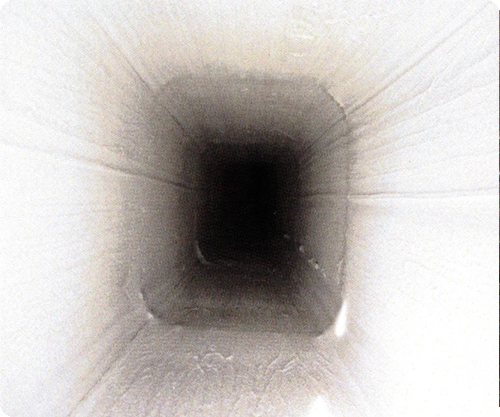

2. Gap between flue liners as viewed through electronic scanner.

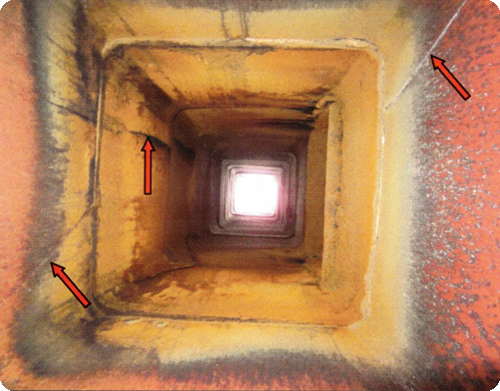

3. Fractured flue liners.

During original construction of a masonry chimney, it is not uncommon for masons to improperly align the flue liners or neglect to fill the joints between the flue liners with the appropriate refractory mortar (images 1 & 2).

As stated in the 2006 International Residential Code, R1003.12 Flue lining (installation): “Fireclay flue liners shall be laid in medium-duty refractory mortar conforming to ASTMC 199 with tight mortar joints left smooth on the inside…”

Additionally, thermal shock caused by chimney fires or over-firing of an appliance or fireplace caused clay flue liners to fracture (image 3). Settling or seismic vibration during an earthquake also caused flue liners to shift and fracture.

The Danger

Improper building practices, thermal shock, settling, or seismic vibration can all contribute to dangerous openings within the flue. These openings can allow heat to escape the flue system possibly exposing surrounding framing to fire risk. Flammable creosote (by-products from wood combustion) build-up may also form outside of the flue lining where cleaning can’t reach. Should these flammable deposits ignite, the heat and quite possibly the flame could transmit to the dwelling.

As recommended by the National Fire Protection Agency 211 – Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, “If the flue liner in a chimney has softened, cracked or otherwise deteriorated so that it no longer has the continued ability to contain the products of combustion (ie:, heat, moisture, creosote, and flue gases), it shall be either removed and replaced, repaired, or relined.” In the past, relining was the only option.

Now, you and your chimney professional have a viable, safe alternative to relining with Stainless steel. FireGuard; it is the most effective resurfacing product available that addresses dangerous gaps, fractures, and deterioration in flue liners.

The Solution

The patented FireGuard ceramic system is certified, listed, and labeled by Guardian Fire Testing Laboratory, Inc. (ISP 17025) as a repair system for damaged or defective clay flue liners. The FireGuard system is the only certified, ceramic resurfacing and mortar joint repair system employing pinpoint vibration, which promotes maximum penetration of tight mortar joints and fractures, and a consistent coat distribution for resurfacing. Without pinpoint vibration, the ceramics do not penetrate tight openings nor form a solid, consistent coating over surfaces.

FireGuard temperature rating, 3,205 F , is the highest rating in the industry. The unique chemical and physical properties of the FireGuard pure ceramic material and the method by which it is applied product heat, acid, and water resistant surfaces and joints that decrease dangerous heat transfer and virtually eliminate gas seepage through the flue liners. The FireGuard system can be installed in any size or shape flue liner.

The Procedure

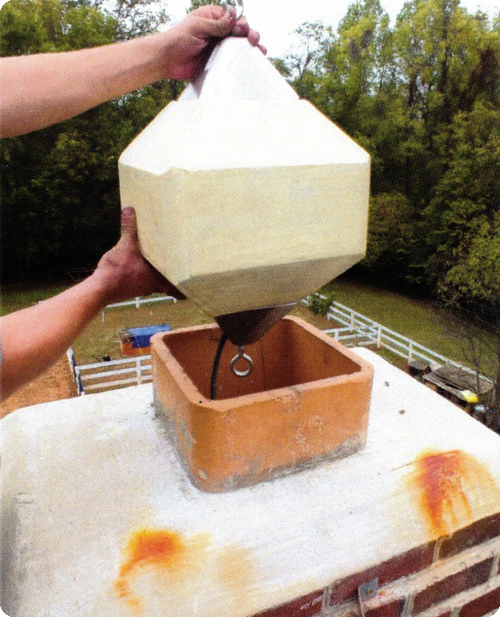

1. Closed-cell applicator with an internal vibrator is installed in the top of the flue & winched down to the base of the flue.

2. The FireGuard material is then blended and poured on top of the vibrating applicator as it is winched up the flue. The applicator is drawn up and down the flue for multiple passes.

3. Top winch is used to pull the vibrating applicator up the flue.

The Finished Product

1. Open mortar joint solidly filled.

2. Fractured flue liners completely resurfaced.

3. Off-set between flue liners solidly filled.

Why You Should Consider the FireGuard Alternative.

The FireGuard process is protected under United States patent laws (“patented”).